The weather has driven the project indoors, so the work tables have been placed and leveled, and work continues on the lower center wing section.

|

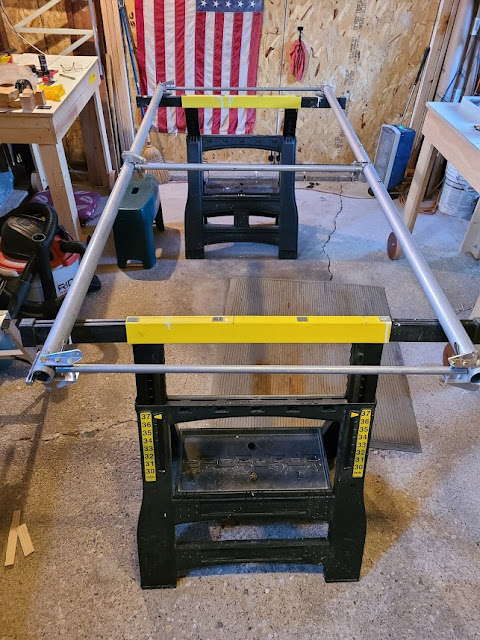

Wide-angle view of the shop area. |

The weather has driven the project indoors, so the work tables have been placed and leveled, and work continues on the lower center wing section.

|

Wide-angle view of the shop area. |

Finally, time to build what most people would associate with an airplane (technically a 'vehicle' since this is an FAR Part 103 ultralight) - a wing. Only one new skill is anticipated: assembly of stainless steel cable, thimbles and Nicopress sleeves.

|

| Wing assembly well under way. |

|

| Use of vinyl tape to assure a closer fit between main spar and inner reinforcement tubes. In this case, two thicknesses. |

|

| Place the bushing and slide the tang over the thimble and into the bushing slot... |

|

| Restore the thimble to its original shape. |

|

| Nicopress sleeves and press. |

|

| Squaring up the frame by measuring diagonally across four long temporary bolts at the corners. Fixed in place with a wood scrap and clamps |

|

| Other side (out of picture) pre-crimped, getting ready to crimp this side. |

|

| Rib bending table with full-sized template as a guide |

|

| The end ribs are riveted and braced. The inner six ribs will be 'floating' - secured with epoxy/fiberglass bands. |

|

| Stanley saw horses were on hand and worked well enough. |

|

| Finishing some ribs. Used ViseGrips, jaws partially open about 1/4", to work the ends closed. Touched up on a piece of steel rail (train track) using a bronze hammer. Clear shipping tape keeping the template usable. |

|

| Ribs in place. |

|

| Rib ends temporarily taped in place with vinyl tape. |

|

| Another view. This was the last good weather day for the season. Shop moved back into the basement until spring. Sigh... |

|

| Bending the trailing edge tubes. |

|

| Test fitting the Elevator Control Horn Assembly |

|

| Fitting the ribs for gluing. |

|

| Setting up two leveled tables for rib fitting. |

|

| Wire used to keep inner reinforcing tube from shifting out of place. |

|

| Kitchen microplane used on foam to achieve desired shape. |

|

| Leveling out temporary ceiling hangers. |

|

| Epoxy layup of fiberglass. Painters tape helps keep ends in place during curing. |

|

| The day was a bit cooler than optimal for epoxy cure. Sunshine helped out. |

Looking forward to giving my epoxy skills a rest. I'll be focusing next on the center wing sections, so it will be awhile before I'll need to indulge again.

Now that I've completed the rudder and horizontal stabilizer, the vertical stabilizer should be a breeze, right? Well, yes, it was getting easier.

|

| Garage tech indeed. |

Fitting the cross braces amounted to aligning the foam with small pencil marks and using my thumbnail to score a line. Cutting with a bare hacksaw blade, a hair oversize, then bringing down to size with a 100 grit garnet paper sanding block.

As learned previously, I layed-up the short brace pieces of fiberglass tape first, then glued the longer pieces over them. I also made use of the microballoon filler after the initial gluing. Also, paste waxing the melamine work surface worked like a charm in resisting any stray epoxy.

|

| The top and bottom are coated with epoxy to resist the eventual melting effects of the Dacron covering chemicals. |

|

| High tech, it ain't. |

|

| Holding off on drilling holes until ready to assemble. |

|

| Hanging from ceiling makes placing fiberglass tape much easier. |

Remember that expression, "Never time to do it right, but always time to do it over?" Fits my experience with the horizontal stabilizer. After days of cutting ribs, gluing, installing and fiberglass-epoxy layup, I was not thrilled to learn that I'd oriented the rear tube 90° out of position:

|

| That bolt in the foreground should be 90° clockwise. Doh! |

|

| Post-op, patient recovering nicely. |

While in the garage, working on the horizontal stabilizer, I caught something out of the corner of my eye that was out of place. What I assume was an escaped pet parakeet.

|

| Unexpected volunteer. |

|

| Pretty lethargic and probably hungry. |

|

| Turns out she had quite an appetite. |

|

| Pining for the fjords, no doubt. |

|

| Temporary bolt aligns parts for drilling. |

|

| Marking parts will help later, right? |

|

| Guard Chihuahua keeps unauthorized insects out of the garage workshop! |

|

| Gluing rudder braces and ribs with 'shim' clamps. |

|

| Rudder almost ready for covering. |