Finally, time to build what most people would associate with an airplane (technically a 'vehicle' since this is an FAR Part 103 ultralight) - a wing. Only one new skill is anticipated: assembly of stainless steel cable, thimbles and Nicopress sleeves.

|

| Wing assembly well under way. |

|

| Use of vinyl tape to assure a closer fit between main spar and inner reinforcement tubes. In this case, two thicknesses. |

|

| Place the bushing and slide the tang over the thimble and into the bushing slot... |

|

| Restore the thimble to its original shape. |

|

| Nicopress sleeves and press. |

|

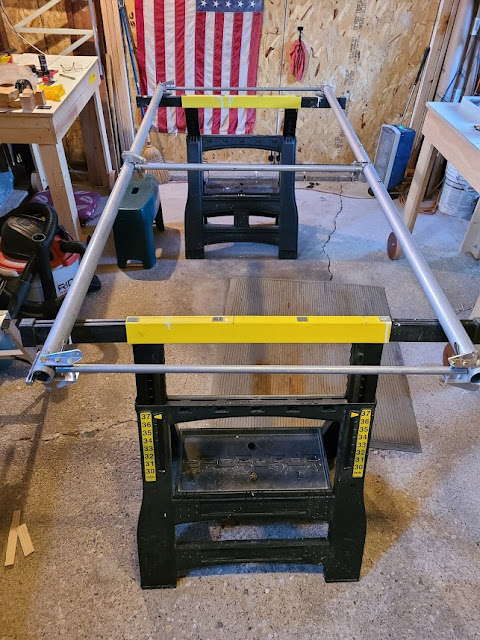

| Squaring up the frame by measuring diagonally across four long temporary bolts at the corners. Fixed in place with a wood scrap and clamps |

|

| Other side (out of picture) pre-crimped, getting ready to crimp this side. |

|

| Rib bending table with full-sized template as a guide |

|

| The end ribs are riveted and braced. The inner six ribs will be 'floating' - secured with epoxy/fiberglass bands. |

|

| Stanley saw horses were on hand and worked well enough. |

|

| Ribs in place. |

|

| Rib ends temporarily taped in place with vinyl tape. |

|

| Another view. This was the last good weather day for the season. Shop moved back into the basement until spring. Sigh... |