Static test at full throttle:

Building Sandlin's Bloop

Tuesday, August 9, 2022

Sunday, July 31, 2022

Thursday, January 20, 2022

Lower, center wing: perimeter/finish tapes applied, primer next...

Fast forward after three cross-coats of primer and four coats of latex:

Saturday, September 4, 2021

Tuesday, December 1, 2020

Wing: Ribs, Leading and Trailing Edges

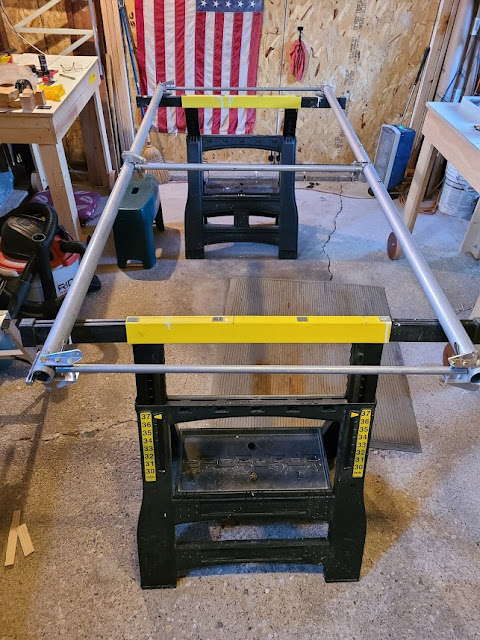

The weather has driven the project indoors, so the work tables have been placed and leveled, and work continues on the lower center wing section.

|

Wide-angle view of the shop area. |

Sunday, October 18, 2020

Building the Wing (Well, 1 of 6 Anyway)

Finally, time to build what most people would associate with an airplane (technically a 'vehicle' since this is an FAR Part 103 ultralight) - a wing. Only one new skill is anticipated: assembly of stainless steel cable, thimbles and Nicopress sleeves.

|

| Wing assembly well under way. |

|

| Use of vinyl tape to assure a closer fit between main spar and inner reinforcement tubes. In this case, two thicknesses. |

|

| Place the bushing and slide the tang over the thimble and into the bushing slot... |

|

| Restore the thimble to its original shape. |

|

| Nicopress sleeves and press. |

|

| Squaring up the frame by measuring diagonally across four long temporary bolts at the corners. Fixed in place with a wood scrap and clamps |

|

| Other side (out of picture) pre-crimped, getting ready to crimp this side. |

|

| Rib bending table with full-sized template as a guide |

|

| The end ribs are riveted and braced. The inner six ribs will be 'floating' - secured with epoxy/fiberglass bands. |

|

| Stanley saw horses were on hand and worked well enough. |

|

| Finishing some ribs. Used ViseGrips, jaws partially open about 1/4", to work the ends closed. Touched up on a piece of steel rail (train track) using a bronze hammer. Clear shipping tape keeping the template usable. |

|

| Ribs in place. |

|

| Rib ends temporarily taped in place with vinyl tape. |

|

| Another view. This was the last good weather day for the season. Shop moved back into the basement until spring. Sigh... |

Elevator Build

|

| Bending the trailing edge tubes. |

|

| Test fitting the Elevator Control Horn Assembly |

|

| Fitting the ribs for gluing. |

|

| Setting up two leveled tables for rib fitting. |

|

| Wire used to keep inner reinforcing tube from shifting out of place. |

|

| Kitchen microplane used on foam to achieve desired shape. |

|

| Leveling out temporary ceiling hangers. |

|

| Epoxy layup of fiberglass. Painters tape helps keep ends in place during curing. |

|

| The day was a bit cooler than optimal for epoxy cure. Sunshine helped out. |

Subscribe to:

Comments (Atom)