|

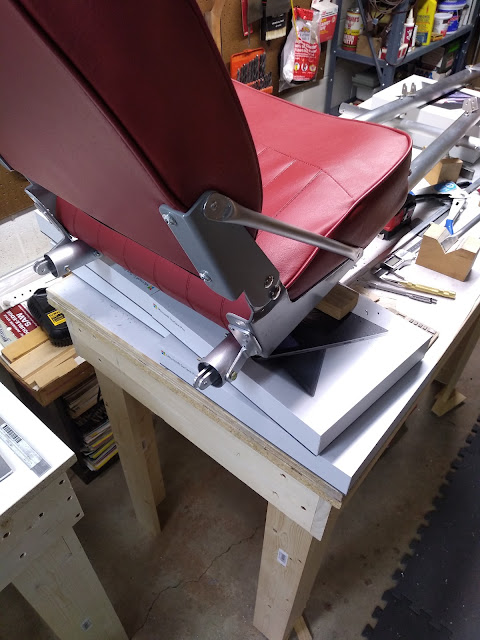

| The designer's version. With luck mine will resemble this one day. |

Over thirty years ago, I started toward my goal of obtaining a private pilot's license. A handful of lessons later, my job, family and finances conspired and pushed that dream onto the back burner. Actually, it fell behind the stove, joining other unrealized dreams: race car driver, astronaut and rock star.

In time, pilot's license medical certificate health requirements (and my inability to meet them) made my piloting goal completely academic. Or so I thought until last February when I came across a story about a Madison, Wisconsin

researcher flying a

Part-103 ultralight known as a

Zigolo. Turns out there was a way to fly without a medical certificate - or a license for that matter. As long as the 'vehicle' met certain FAA-required parameters (maximum weight, stall speed, fuel capacity etc.) one technically

could fly without any training whatsoever. Kind of like acting as your own attorney, but with more serious consequences.

Over the next year, that initial spark led to the Bloop and many other ultralights: Weedhopper, Sky Pup, Pouchel; even Gyroplanes. Mostly though, all shared important traits in common: two-axis flight control, solid design and (seeming) forgiveness in the hands of a low-time pilot. Plans were bought and studied. Forums joined. False starts started, and stopped. When the dust had cleared and having come with inches of starting a

Pouchel build, I had returned back to my first infatuation, the

Bloop.

Over the next four to forty months, I plan to continue to reach for (what I hope is) the lofty goal of flight. I've already started fabrication and will document that process in this blog.

-GH